Production

Voortman is known for its dedication to service and support. It is the industry's gold standard. Voortman provides a global team for customer support that is available 24/7 at the Voortman Customer Support Center. Voortman supports you with state-of-the art remote diagnostic software, local field support and an industry-leading warranty.

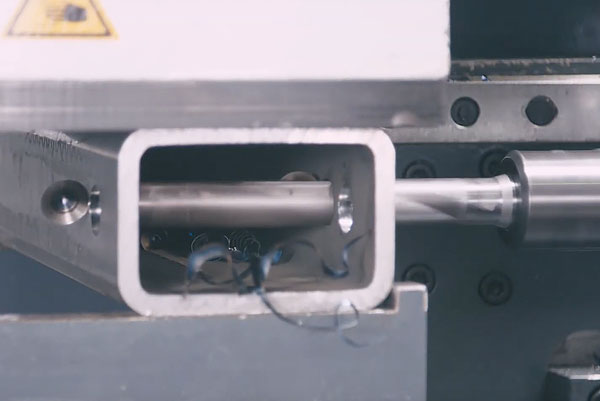

GSS Machinery offers a variety of drilling options to drill with your CNC Beam Drill Line.